E-rickshaws have transformed urban transportation across Asia, offering an affordable and eco-friendly alternative for short-distance travel. While most people focus on the battery capacity and motor power, there’s an unsung hero working silently beneath the chassis: the differential. This critical component is what separates a smooth, efficient ride from a jerky, maintenance-heavy nightmare.

Understanding the Differential: More Than Just Gears

At its core, a differential is an ingenious gearbox positioned between the drive wheels. Think of it as the vehicle’s way of solving a geometric problem that occurs every time you make a turn.

When an e-rickshaw navigates a corner, the outer wheel must travel a longer arc than the inner wheel. Without a differential forcing both wheels to spin at identical speeds, something has to give—usually your tyres, your passenger’s comfort, or your drivetrain components. The differential elegantly solves this by allowing each wheel to rotate independently while still receiving power from the motor.

The Real-World Impact: Why It Matters for E-Rickshaw Operations

Maneuverability in Tight Urban Spaces

E-rickshaws thrive in congested marketplaces, narrow residential lanes, and busy intersections where larger vehicles struggle. A differential transforms these challenging environments from obstacle courses into manageable routes. Drivers gain precise control during turns, passengers experience less jostling, and the overall ride quality improves dramatically. Without this component, every corner becomes an exercise in fighting the vehicle’s natural tendency to resist direction changes.

Economic Benefits: Saving Money Where It Counts

For drivers operating on thin margins, every rupee matters. A differential directly impacts the bottom line in several ways. Tyres last significantly longer because they’re not constantly scrubbing against the road surface during turns. The extended lifespan means fewer replacements and more days of revenue-generating operation. Additionally, reduced mechanical wear translates to fewer breakdowns and lower repair bills—critical advantages when competing in the shared mobility market.

Protecting Your Investment

The drivetrain of an e-rickshaw represents a substantial investment. Without a differential, turning forces create enormous stress on axle shafts, bearings, and motor couplings. Over time, this relentless strain leads to premature failures that could have been prevented. A properly functioning differential acts as a mechanical buffer, absorbing these forces and distributing them in ways that preserve component integrity.

Maximizing Range: Every Kilometer Counts

Battery anxiety is real for e-rickshaw drivers. A differential contributes to energy efficiency by eliminating the power wastage that occurs when wheels fight each other during turns. While the improvement per turn might seem negligible, thousands of turns per day add up to meaningful range extensions. This can mean the difference between completing that last fare of the day or heading home early to recharge.

Choosing the Right Differential Type

Open Differential: The Workhorse Standard

The vast majority of e-rickshaws roll off assembly lines equipped with open differentials, and for good reason. Their straightforward design keeps manufacturing costs down while providing reliable performance on typical urban terrain. Maintenance is simple, replacement parts are readily available, and mechanics across the country know how to service them. For operators working primarily on paved city roads, an open differential offers the best balance of functionality and affordability.

Limited Slip Differential: The Premium Option

Some manufacturers offer e-rickshaws with limited slip differentials, particularly in models designed for heavier loads or variable terrain. These sophisticated units can redirect torque from a slipping wheel to one with better traction, providing superior handling on unpaved roads, during monsoon conditions, or when navigating steep inclines. The added cost makes sense for operators in areas with challenging road conditions or those regularly carrying maximum passenger loads.

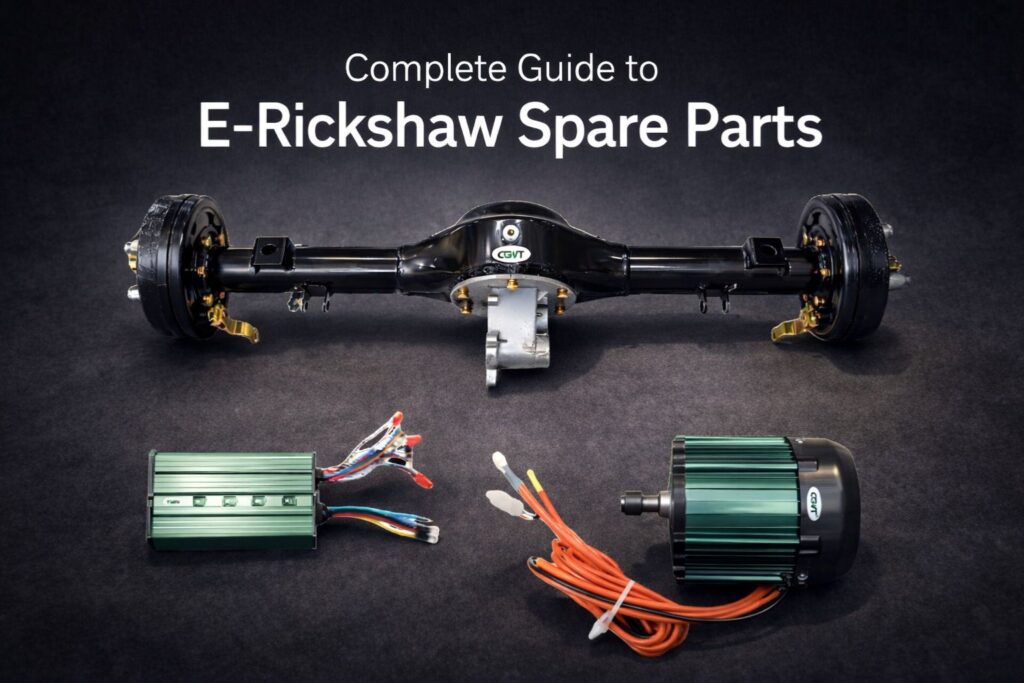

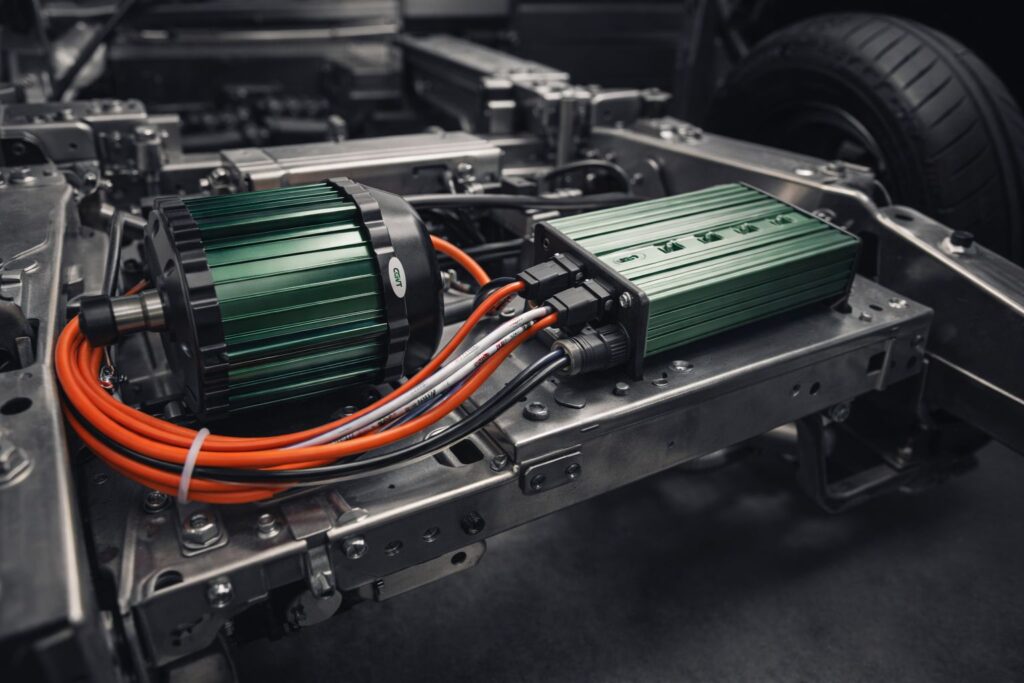

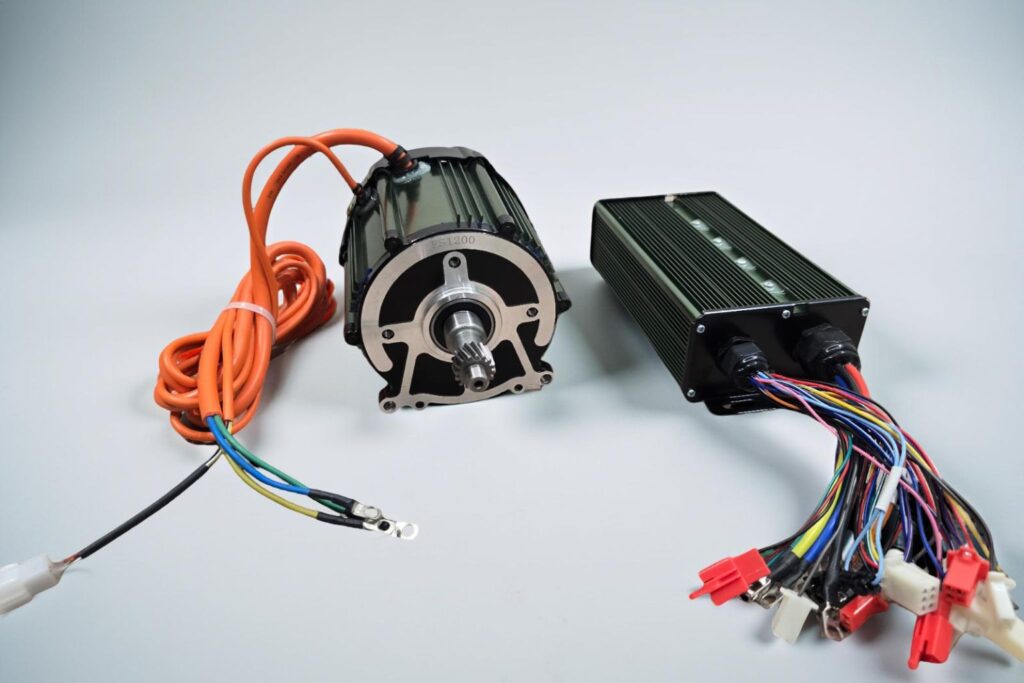

Integrated Differential Axle: The Future Is Here

The latest generation of e-rickshaws increasingly features motor-integrated differential axles. These compact assemblies combine the motor, differential, and axle into a single unit, reducing weight, minimizing power losses, and simplifying the drivetrain. While initially more expensive, they represent the direction the industry is heading as manufacturers prioritize efficiency and reliability.

Differential vs. Direct Drive: Understanding the Tradeoffs

Some budget e-rickshaws eliminate the differential entirely, using direct drive systems where both wheels are locked together. While this reduces initial purchase price, the long-term costs tell a different story. Turning becomes noticeably more difficult, requiring greater steering effort. Tyres wear unevenly and need replacement more frequently. Passengers complain about the jerky ride quality. Energy consumption increases. Mechanical failures become more common.

The modest upfront savings quickly evaporate when factoring in higher operating expenses and lost revenue from breakdowns and customer dissatisfaction.

Maintenance: Keeping Your Differential Healthy

A differential is remarkably durable when properly maintained but can fail catastrophically when neglected. Follow these essential practices:

Regular Inspection Schedule: Check the differential housing for leaks every week and listen for unusual grinding or whining sounds that indicate internal wear. Early detection of problems prevents costly failures.

Lubrication Management: Whether your differential uses oil or grease, maintaining proper levels and quality is non-negotiable. Follow manufacturer intervals for changes, typically every 10,000 to 15,000 kilometers. Using the correct lubricant specification isn’t optional—substituting products can lead to premature wear.

Load Awareness: Consistently overloading your e-rickshaw accelerates differential wear. Those extra passengers or cargo might seem harmless, but they place exponential stress on gear teeth and bearings.

Professional Service: While basic checks can be done independently, have a qualified mechanic perform detailed inspections during routine service. They can detect wear patterns and potential failures before they leave you stranded.

The Bottom Line: Essential, Not Optional

As e-rickshaw technology continues evolving, the differential remains a fundamental component that separates reliable, efficient vehicles from problematic ones. Whether you’re a driver maximizing daily earnings, a fleet operator managing costs, or a manufacturer designing the next generation of electric vehicles, understanding differential systems is crucial.

The best e-rickshaws on the road today prove that sustainable urban mobility requires more than just an electric motor and battery pack. It demands thoughtful engineering throughout the vehicle, with the differential playing a starring role in ensuring smooth operation, passenger satisfaction, and long-term profitability.

Investing in a quality differential—and maintaining it properly—isn’t an expense. It’s an investment in smoother rides, happier passengers, lower operating costs, and a vehicle that keeps earning money year after year.

For more insights on e-rickshaw technology, maintenance tips, and the latest developments in electric mobility, visit cgvt.in — your comprehensive resource for understanding and optimizing electric vehicle performance.