Whether you’re a fleet owner, a self-employed driver, or a spare parts dealer — understanding every component of your e-rickshaw is the difference between a profitable vehicle and an expensive breakdown. This guide covers everything you need to know about e rickshaw spare parts: what they are, what they do, and how to buy them wisely.

The electric rickshaw has transformed last-mile connectivity across South Asia and beyond. With millions of units on the road today, the demand for e rickshaw spare parts has never been higher. Yet many owners still make costly mistakes — buying substandard components, neglecting preventive replacements, or overpaying due to lack of knowledge.

This guide is your complete roadmap. By the end, you’ll know exactly which parts matter most, how each one functions within the vehicle, and how to make smart purchasing decisions every single time.

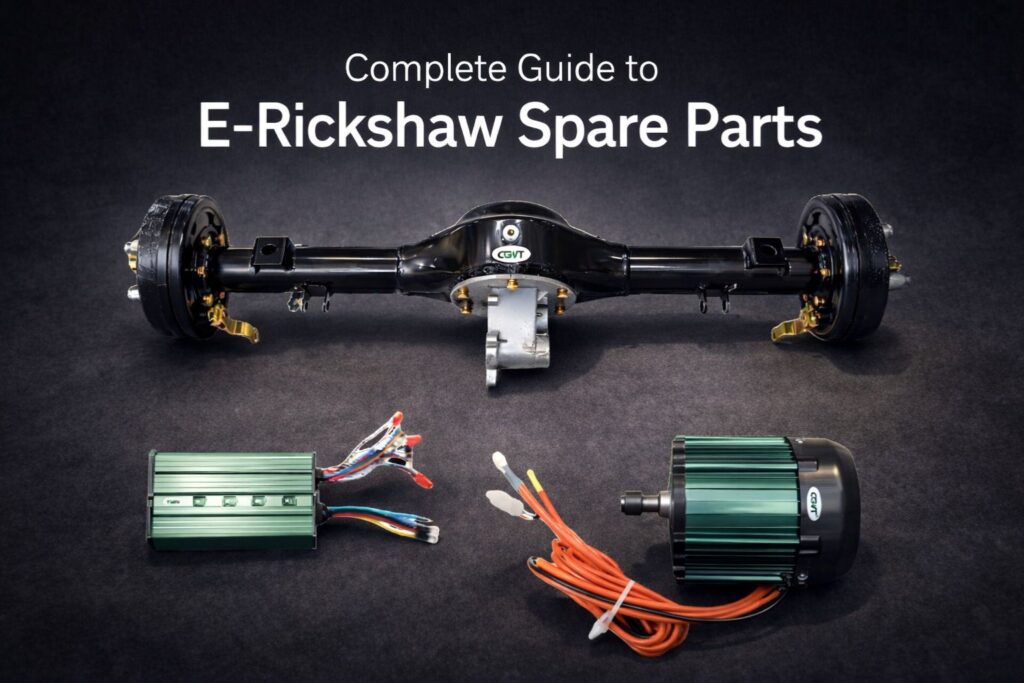

What Are E Rickshaw Spare Parts?

E rickshaw spare parts are the individual components and assemblies that make up an electric rickshaw’s mechanical, electrical, and structural systems. Unlike conventional auto-rickshaws that run on fuel, e-rickshaws rely on a combination of battery power, electric motor technology, and a simplified drivetrain — which means the spare parts ecosystem is unique, highly specialized, and constantly evolving.

These parts are broadly categorized into: the electrical system (battery, controller, motor, charger), the mechanical system (axle, suspension, brakes, tyres), the body & structural components (chassis, seat, roof), and miscellaneous accessories (horn, lights, indicators, wiring harness).

“A well-maintained e-rickshaw can run 80,000 km+ before a major overhaul — if the right spare parts are used at the right time.”

Complete List of E Rickshaw Spare Parts

Below is a comprehensive breakdown of all major e rickshaw spare parts, organized by system category:

Electrical Components:

| Part 01 Battery Pack The heart of the e-rickshaw. Typically 48V or 60V lead-acid or lithium-ion, 100–200Ah capacity. | Part 02 BLDC Motor Brushless DC hub motor at the rear axle. Converts electrical energy into wheel rotation. 650W–1500W ratings. |

| Part 03 Motor Controller Regulates power flow from battery to motor, controls speed, torque, and protects against electrical faults. | Part 04 Battery Charger Converts AC mains to regulated DC for charging. Smart chargers prevent overcharging and extend battery life. |

| Part 05 Throttle Assembly Handlebar-mounted twist grip sending speed commands to controller. Hall sensor or resistive types available. | Part 06 Wiring Harness Complete cable assembly connecting all electrical components. Damage causes erratic behavior and short circuits. |

| Part 07 BMS (Battery Mgmt) Battery Management System monitoring cell health, temperature, and charge/discharge cycles. | Part 08 DC-DC Converter Steps down high-voltage battery output to 12V for lights, horn, indicators, and other accessories. |

Mechanical & Drivetrain Components

| Part 09 Rear Axle Assembly Houses the hub motor and differential. Critical load-bearing component transferring torque to rear wheels. | Part 10 Front Fork Suspension and steering assembly for the front wheel. Hydraulic or spring dampers absorb road shocks. |

| Part 11 Brakes (Drum/Disc) Mechanical or hydraulic braking system. Most e-rickshaws use drum brakes; some models use disc brakes. | Part 12 Tyres & Tubes Typically 4.00-8 size rear and 3.50-8 front. Tubeless variants available for reduced puncture risk. |

| Part 13 Wheel Rims Steel spoke rims supporting tyres. Subject to bending on rough roads. Alloy rims are lighter and more durable. | Part 14 Leaf Springs/Shocks Suspension protecting passengers and battery from vibration. Worn springs increase battery bracket stress. |

| Part 15 Steering & Tie Rods Connect handlebar to front wheel and maintain alignment. Worn tie rods cause wobbling and uneven tyre wear. | Part 16 Brake Cables/Liners Flexible cables transmitting braking force and friction material inside drum brakes. High-wear consumables. |

Body & Structural Parts

| Part 17 Chassis Frame Main steel tubular backbone of the vehicle. Load rating determines passenger and battery capacity. | Part 18 Body Panels FRP (fibreglass reinforced plastic) side, front, and rear panels. Lightweight and corrosion-resistant. |

| Part 19 Roof / Hood FRP or canvas canopy protecting passengers. Some models include solar panel-compatible roof mounts. | Part 20 Seat Assembly Driver seat (front) and passenger bench seat (rear). Foam-padded with leatherette covers. 3–4 passenger capacity. |

| Part 21 Footboard & Floor Panel Steel or fibreglass floor panels protecting the underbody and providing passenger footing. | Part 22 Battery Box/Tray Steel enclosure securing battery packs under the seat. Must be corrosion-resistant with proper ventilation. |

Accessories & Miscellaneous

| Part 23 Headlights & Taillights LED lighting assemblies front and rear. LED variants last significantly longer than halogen alternatives. | Part 24 Horn 12V electric horn. A legally required safety accessory. Disc-type horns are most common. |

| Part 25 Indicators/Blinkers Turn signal lights (4-way) with flasher relay. LED versions improve visibility and reduce power consumption. | Part 26 Speedometer/Display LCD or analogue instrument cluster showing speed, battery level, odometer, and error indicators. |

Parts Priority: What to Replace First

Not all e rickshaw spare parts wear at the same rate. Understanding which components are critical — and scheduling replacements proactively — saves you from expensive emergency breakdowns.

| Part | Average Lifespan | Priority | Replacement Trigger |

| Lead-Acid Battery | 12–18 months | CRITICAL | Range drops below 40% of rated capacity |

| Brake Liners | 8,000–12,000 km | CRITICAL | Grinding noise, increased stopping distance |

| Tyres | 15,000–25,000 km | CRITICAL | Tread depth < 1.6mm, visible cracks |

| Motor Controller | 2–4 years | IMPORTANT | Erratic speed, overheating, error codes |

| Throttle | 1–2 years | IMPORTANT | Jerky acceleration, stuck at full speed |

| Suspension Springs | 2–3 years | IMPORTANT | Excessive body roll, bottoming out |

| Wiring Harness | 3–5 years | IMPORTANT | Intermittent electrical faults, exposed wires |

| Headlights (LED) | 3–5 years | Standard | Dimming, flickering, complete failure |

| Seat Covers | 1–2 years | Standard | Tears, foam exposure, hygiene concerns |

| Body Panels | 4–7 years | Standard | Major cracks, structural damage |

Pro Tip: The Battery-Controller Relationship

Always replace the battery charger when you replace your battery pack. An old charger can be miscalibrated for a new battery’s voltage profile, leading to undercharging, overcharging, or reduced new-battery lifespan. It’s one of the most overlooked — and most costly — mistakes e-rickshaw owners make.

Functions of Key E Rickshaw Spare Parts Explained

Understanding what each part does helps you diagnose problems faster and communicate more effectively with mechanics and suppliers.

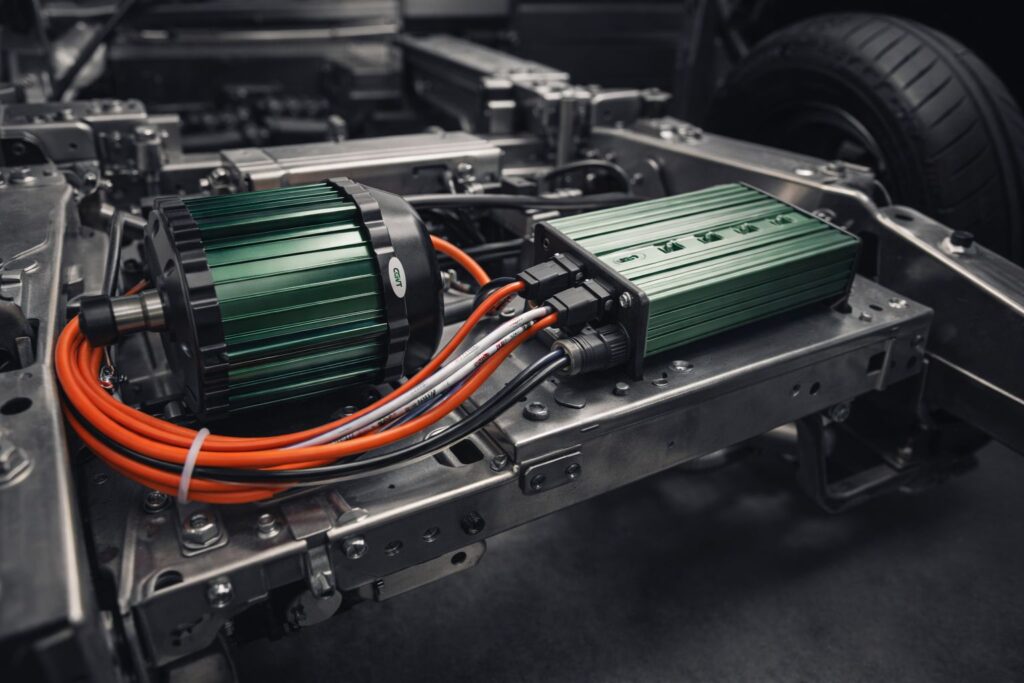

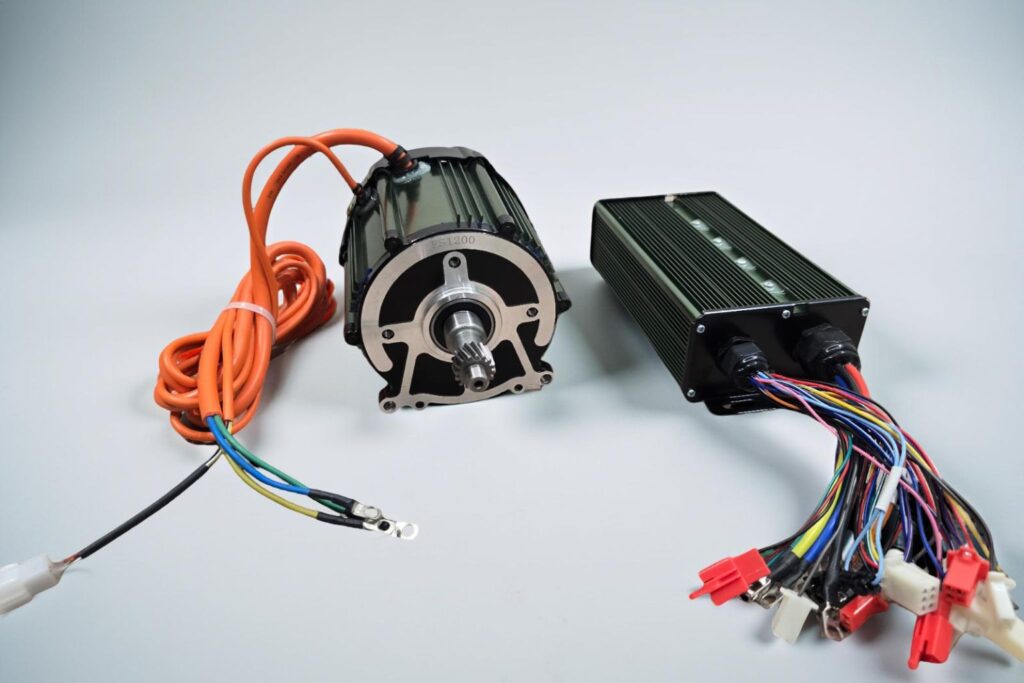

How the BLDC Motor Works

The Brushless DC (BLDC) hub motor is the primary propulsion unit. Unlike brushed motors, it has no physical contact between rotor and stator — electronic commutation via the controller keeps the rotor spinning efficiently. This means less heat, less friction, longer lifespan, and higher efficiency (typically 85–92% efficiency vs. 75–85% for brushed motors). The motor’s wattage rating determines the vehicle’s climbing ability and top speed.

How the Motor Controller Works

The controller interprets throttle input and translates it into precise electrical pulses (PWM signals) delivered to the motor windings. It also manages regenerative braking, overvoltage/undervoltage protection, thermal shutdown, and current limiting. A failing controller is often responsible for sudden loss of power, motor overheating, or the vehicle only working at full throttle.

How the BMS Protects Your Battery

The Battery Management System continuously monitors individual cell voltages within the pack. If any cell drops too low (over-discharge) or goes too high (overcharge), the BMS disconnects the circuit. It also balances cells to ensure uniform charge distribution — the single biggest factor determining long-term battery health. Skipping a BMS leads to premature battery failure.

Expert Buying Tips for E Rickshaw Spare Parts

Buying the wrong e rickshaw spare parts wastes money and can damage other components. Follow these expert tips before every purchase:

1. Always buy OEM or OEM-equivalent parts. Original Equipment Manufacturer parts are designed specifically for your vehicle model. Third-party parts may have mismatched voltage ratings or physical dimensions.

2. Check the voltage and ampere rating before buying electrical parts. Installing a 48V controller on a 60V system can destroy both the controller and the motor. Always match the system voltage precisely.

3. Verify your vehicle’s make and model number. The same brand can produce different variants with different part specifications. The model number is on a chassis plate near the seat.

4. For batteries, always buy from brands with ISI or BIS certification. Certified batteries meet minimum safety and performance standards. Uncertified batteries may have inflated capacity claims and present fire risks.

5. Compare prices across at least three suppliers before buying. The e rickshaw spare parts market has significant price variance. Online platforms, local dealers, and direct manufacturers all offer different pricing.

6. Insist on warranty documentation for major parts. Batteries should carry minimum 6-month warranty, motors 12 months, and controllers 6 months. Avoid suppliers unwilling to provide written warranty terms.

7. Buy tyres from reputable brands with load index matching. The tyre load index must meet or exceed the maximum laden weight of your e-rickshaw. Common reputable brands include MRF, Apollo, and CEAT.

8. For brake components, never compromise on price. Brake liners and cables are safety-critical. Cheap liners may have inconsistent friction coefficients — especially dangerous in wet conditions.

9. Consider buying consumables in bulk. Items like brake liners, tubes, and wiring connectors are needed regularly. Buying 3–6 units at a time saves 15–25% versus single-unit purchases.10. Ask your mechanic first — before you buy. A good mechanic can tell you exactly which part failed and recommend compatible alternatives. Buying parts before diagnosis often results in purchasing the wrong component.

Where to Buy E Rickshaw Spare Parts

Authorized Service Centers: The safest option for warranty-valid parts. Prices are higher but parts are guaranteed to be genuine and compatible with your vehicle model. Best for batteries, motors, and controllers.

Wholesale Spare Parts Markets: Cities like Delhi (Kashmere Gate), Kanpur, Agra, and Patna have established e-rickshaw spare parts wholesale markets where you can buy components at 20–40% below retail.

Online Marketplaces: Platforms such as IndiaMART, TradeIndia, and Amazon India carry a wide range. Always check seller ratings, reviews, and return policies before purchasing electrical components online.

Direct from Manufacturers: For fleet operators needing large quantities, purchasing directly from manufacturers (especially for batteries and chargers) offers the best pricing and often includes delivery and installation support.

Watch Out for Counterfeits

The e rickshaw spare parts market is unfortunately rife with counterfeit components, particularly batteries and controllers. Look for holographic authenticity stickers, buy from authorized distributors when possible, and be suspicious of prices significantly below market average — if a battery costs half of what you’d expect, it’s almost certainly not what the label claims.

Maintenance Schedule: Preventing the Need for Spare Parts

The best way to manage e rickshaw spare parts costs is to reduce the frequency of unplanned replacements through disciplined preventive maintenance. Here’s a quick-reference maintenance calendar:

| Frequency | Maintenance Task |

| Daily | Check tyre pressure, inspect brake function, check battery water level (lead-acid) |

| Weekly | Clean battery terminals, check all lights and horn, inspect brake cable tension |

| Monthly | Inspect wiring harness for wear, check suspension components, clean motor vents |

| Every 3 Months | Check steering alignment, inspect brake liners, check all bolts and fasteners |

| Every 6 Months | Professional service inspection, battery capacity test, controller diagnostics |

| Annually | Full vehicle inspection, brake system overhaul, suspension refresh, tyre rotation |

Conclusion

Managing e rickshaw spare parts effectively is a skill that directly impacts your vehicle’s uptime, safety, and profitability. The key takeaways are simple: know your parts, understand their functions, follow a preventive maintenance schedule, and never compromise on safety-critical components like brakes and batteries.

Whether you own a single e-rickshaw or manage a fleet, the investment you make in quality spare parts always pays back — in fewer breakdowns, longer vehicle life, and happier passengers. The next time a component needs replacing, you’ll know exactly what to buy, where to buy it, and why it matters.

Have questions about a specific e rickshaw spare part not covered here? Share it with your mechanic or authorised dealer for expert guidance.